More Post from the Author

- VERTEX Strengthens Leadership Team with Key Executive Appointments and New Board Members

- Waters Corporation Schedules Second Quarter 2025 Earnings Conference Call

- Nuvei se asocia con flaconi para impulsar el crecimiento europeo de la cadena de belleza y fragancias

- Why Property Managers Are Losing ROI Without Modern Inspection Software--And the Smart Way to Fix It

- Granite State Gaming & Hospitality Partners with Gaming Analytics to Power Data-Driven Guest Experiences Across Lilac Club Casino and Beach Club Casino

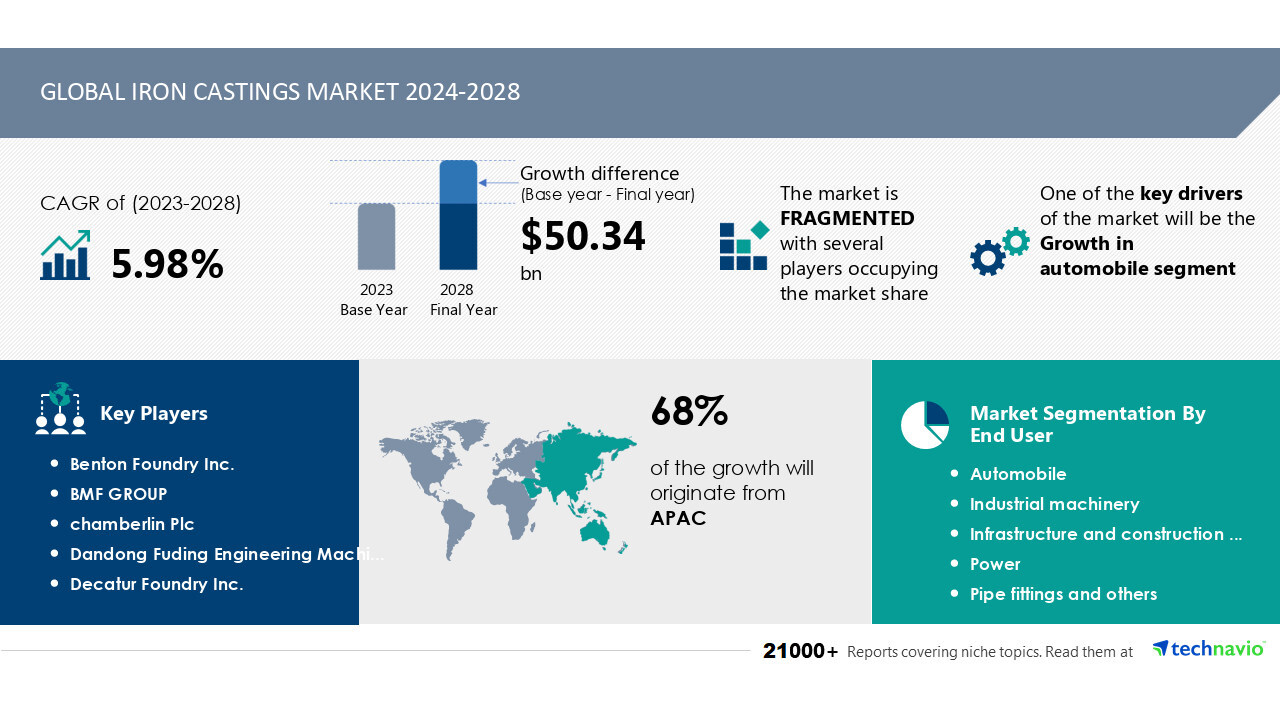

Iron Castings Market to Grow by USD 50.34 Billion (2024-2028), Automobile Segment Expansion Boosts Growth, with AI Redefining Market Landscape - Technavio

NEW YORK, Jan. 31, 2025 /PRNewswire/ -- Report with market evolution powered by AI - The global iron castings marketsize is estimated to grow by USD 50.34 billion from 2024-2028, according to Technavio. The market is estimated to grow at a CAGR of 5.98% during the forecast period. Growth in automobile segmentis driving market growth,with a trend towardsmodernization of foundry industry. However,increasing competition from aluminum casting poses a challenge. Key market players include Benton Foundry Inc., BMF GROUP, chamberlin Plc, Dandong Fuding Engineering Machinery Co. Ltd., Decatur Foundry Inc., Deeco Metals, Hitachi Ltd., MAGMA Giessereitechnologie GmbH, Ningbo Metrics Automotive Components Co. Ltd., OSCO Industries Inc., Plymouth Foundry Inc., POSCO holdings Inc., Proterial Ltd., Qingdao Tian Hua Yi He Foundry Factory, Reliance Foundry Co. Ltd, Shibaura Machine CO. LTD., Sumitomo Electric Industries Ltd., Suzhou Keboer Machine Tool Group Co. Ltd., thyssenkrupp AG, and Willman Industries Inc.

Key insights into market evolution with AI-powered analysis. Explore trends, segmentation, and growth drivers- View Free Sample PDF

Iron Castings Market Scope | |

Report Coverage | Details |

Base year | 2023 |

Historic period | 2018 - 2022 |

Forecast period | 2024-2028 |

Growth momentum & CAGR | Accelerate at a CAGR of 5.98% |

Market growth 2024-2028 | USD 50.34 billion |

Market structure | Fragmented |

YoY growth 2022-2023 (%) | 5.5 |

Regional analysis | APAC, Europe, North America, South America, and Middle East and Africa |

Performing market contribution | APAC at 68% |

Key countries | US, China, India, Japan, and Germany |

Key companies profiled | Benton Foundry Inc., BMF GROUP, chamberlin Plc, Dandong Fuding Engineering Machinery Co. Ltd., Decatur Foundry Inc., Deeco Metals, Hitachi Ltd., MAGMA Giessereitechnologie GmbH, Ningbo Metrics Automotive Components Co. Ltd., OSCO Industries Inc., Plymouth Foundry Inc., POSCO holdings Inc., Proterial Ltd., Qingdao Tian Hua Yi He Foundry Factory, Reliance Foundry Co. Ltd, Shibaura Machine CO. LTD., Sumitomo Electric Industries Ltd., Suzhou Keboer Machine Tool Group Co. Ltd., thyssenkrupp AG, and Willman Industries Inc |

Market Driver

The global Iron Castings Market is experiencing significant growth, driven by the demand for metal components in various industries. The Foundry Industry plays a crucial role in producing iron castings, serving sectors like automotive and machinery production. Ductile iron and gray iron are popular types of castings, with alloy castings and investment casting also gaining traction. Technological advancements in casting processes and foundry equipment are enhancing production techniques and ensuring quality standards. The Steel Industry is a major supplier of raw materials, with trends in sustainable practices and environmental regulations shaping the market. Demand for castings is increasing in end-user industries, leading to pricing strategies and supply chain optimization. Foundry operations face challenges such as casting defects, metallurgical properties, and heat treatment, requiring continuous innovation and cost optimization. Emerging economies are driving market growth, with investment in foundry capacity and industry partnerships. Market segmentation by production techniques, regional markets, and trade policies offers opportunities for growth. Regulatory compliance, industry associations, and market research are essential for navigating the complex iron castings landscape. Customer satisfaction, aftermarket services, and material sourcing are key areas of focus for foundries. Energy efficiency, waste management, and workforce training are also crucial for sustainable practices. Digitalization trends, predictive maintenance, and product innovation are shaping the future of the industry.

In the current iron castings market, advanced manufacturing techniques have become the norm. Automated molding methods, such as mechanized diametric molding for sand molding and continuous casting for chemical sand binding, are widely adopted for their efficiency and consistency. Strict quality standards ensure superior product output. Environmentally-friendly processes, like cold casting, are gaining popularity due to their reduced emissions and waste. Cold casting does not emit harmful gases during the production process, and 90% of molds are recycled. Additionally, the lightweight nature of cold-cast products simplifies handling and shipping, leading to lower energy costs. These modern casting methods offer numerous benefits, including energy savings, reduced waste, and improved product quality.

Request Sampleof our comprehensive report now to stay ahead in the AI-driven market evolution!

- The iron castings market encompasses the production and supply of metal components, primarily made through casting processes, for various industries. Key sectors include automotive and machinery production. The foundry industry faces challenges in meeting global demand, with raw materials sourcing and pricing strategies being crucial. Ductile and gray iron, alloy castings, and investment casting are common types. Technological advancements, such as digitalization trends and predictive maintenance, are driving innovation. Quality standards, supply chain management, and foundry equipment are essential for operational efficiency. Emerging economies present opportunities for growth, but regulatory compliance and environmental regulations pose challenges. Customer preferences, product differentiation, and cost optimization are key considerations for foundries. Industry partnerships, market consolidation, and aftermarket services are shaping the future of the market. Market research and forecasts indicate steady growth, with demand trends influenced by end-user industries and technological advancements. Foundries must address casting defects, metallurgical properties, and heat treatment to ensure customer satisfaction. Sustainable practices, energy efficiency, and waste management are increasingly important for long-term success. Workforce training and industry associations are vital for maintaining industry expertise and staying competitive.

- The iron castings market is experiencing significant changes due to technological advancements. Aluminum castings are gaining popularity, enhancing manufacturing competitiveness and creating a global manufacturing landscape with increased competition. Aluminum's adoption for high-speed machinery, high-volume production, and extended machinery operation is on the rise. While iron castings and long-lasting, they have limited applications due to their higher compression strength compared to tensile strength. They are primarily used in columns but not in structural beams. However, iron castings are susceptible to corrosion when exposed to moisture. In contrast, aluminum castings offer a substitute for intricately detailed decorative elements, providing resistance to corrosion and a lighter weight. Both materials have their unique strengths, and the market is evolving to accommodate the advantages of each.

Discover how AI is revolutionizing market trends-Get your access now!

This iron castings market report extensively covers market segmentation by

- End-user

- 1.1 Automobile

- 1.2 Industrial machinery

- 1.3 Infrastructure and construction machines

- 1.4 Power

- 1.5 Pipe fittings and others

- Product

- 2.1 Gray iron

- 2.2 Duct iron

- 2.3 Malleable iron

- Geography

- 3.1 APAC

- 3.2 Europe

- 3.3 North America

- 3.4 South America

- 3.5 Middle East and Africa

- Casting Material

- Casting Process

1.1Automobile- The automobile industry's reliance on iron castings for manufacturing durable and critical components contributes significantly to the market's growth. Modernization and advancements in assembly line equipment and machinery in automotive plants increase the demand for iron castings. With the increasing production volume of vehicles in leading countries like Germany, South Korea, Japan, India, China, and the US, there will be a corresponding rise in the demand for iron castings. Iron castings are utilized extensively in producing engine blocks, cylinder heads, brake discs, drums, and transmission housings due to their excellent heat dissipation, high strength, and ability to withstand high temperatures and pressures. Gray iron is commonly used for brake drums, while ductile iron is preferred for brake discs. The transmission housing, which protects delicate internal components, is another significant application area for iron castings. The global iron castings market is expected to grow as the demand for automobiles increases, driven by the rising production volumes in major manufacturing hubs. In 2021, Germany produced 3096 million cars, Japan produced 6,619.24 million cars, China produced 21,407 million cars, India produced 3631 million cars, and the United States produced 1563.06 million cars. These countries' growing automotive industries will boost the demand for iron castings during the forecast period.

Download a Sampleof our comprehensive report today to discover how AI-driven innovations are reshaping competitive dynamics

The global Iron Castings market is a significant segment of the foundry industry, supplying metal components for various sectors including automotive and machinery production. The market is driven by the demand for durable and high-performance metal components, particularly in the automotive sector. The foundry operations involved in the production of iron castings require careful attention to metallurgical properties, heat treatment, machining processes, and surface finishing to ensure product differentiation and customer preferences. Innovation trends in the industry include cost optimization through foundry capacity expansion, market segmentation, and regional market analysis. Trade policies, regulatory compliance, and industry associations play a crucial role in shaping the market landscape. Market research and forecasts indicate continued growth, driven by customer satisfaction, aftermarket services, material sourcing, energy efficiency, waste management, workforce training, digitalization trends, predictive maintenance, industry partnerships, market consolidation, product innovation, customer engagement, brand positioning, and distribution channels. Casting defects remain a challenge, requiring ongoing research and development efforts to improve product quality and meet evolving customer needs.

The global Iron Castings market is a significant segment of the foundry industry, supplying metal components for various end-user industries. These components are essential in machinery production and the automotive sector, where they are used to manufacture engine blocks, cylinder heads, and other critical parts. The market encompasses different casting processes, including investment casting, sand casting, and others, using raw materials like ductile iron, gray iron, and alloy castings. Technological advancements and emerging economies are driving the market's growth, with innovation trends focusing on cost optimization, energy efficiency, and sustainable practices. The steel industry plays a crucial role in the supply chain, providing raw materials and foundry equipment. Quality standards, production techniques, and casting processes are essential factors in ensuring product differentiation and customer preferences. The market is subject to regulatory compliance, environmental regulations, and trade policies, which impact pricing strategies and industry partnerships. Foundry operations face challenges such as casting defects, metallurgical properties, heat treatment, machining processes, and surface finishing. Market research and market forecasts are crucial for understanding demand trends and market segmentation, with regional markets showing varying growth rates. Market consolidation and industry associations are essential for maintaining competitiveness and promoting best practices. Foundries are adopting digitalization trends, including predictive maintenance and workforce training, to improve efficiency and customer engagement. Aftermarket services, material sourcing, and brand positioning are also critical aspects of the market.

1 Executive Summary

2 Market Landscape

3 Market Sizing

4 Historic Market Size

5 Five Forces Analysis

6 Market Segmentation

- End-user

- Automobile

- Industrial Machinery

- Infrastructure And Construction Machines

- Power

- Pipe Fittings And Others

- Product

- Gray Iron

- Duct Iron

- Malleable Iron

- Geography

- APAC

- Europe

- North America

- South America

- Middle East And Africa

- Casting Material

- Casting Process

7Customer Landscape

8 Geographic Landscape

9 Drivers, Challenges, and Trends

10 Company Landscape

11 Company Analysis

12 Appendix

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio's report library consists of more than 17,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio's comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email:[emailprotected]

Website:www.technavio.com/

SOURCE Technavio

More Post from the Author

- VERTEX Strengthens Leadership Team with Key Executive Appointments and New Board Members

- Waters Corporation Schedules Second Quarter 2025 Earnings Conference Call

- Nuvei se asocia con flaconi para impulsar el crecimiento europeo de la cadena de belleza y fragancias

- Why Property Managers Are Losing ROI Without Modern Inspection Software--And the Smart Way to Fix It

- Granite State Gaming & Hospitality Partners with Gaming Analytics to Power Data-Driven Guest Experiences Across Lilac Club Casino and Beach Club Casino