More Post from the Author

- Redwood Software redfinit l'observabilit de l'automatisation avec Redwood Insights Premium

- Liftoff Announces Confidential Submission of Draft Registration Statement for Proposed Initial Public Offering

- /C O R R E C T I O N -- Educate 360/

- Dan Williams Promoted to Century Fasteners Corp. - General Manager, Operations

- DORSIA DEBUTEERT DE CULTURE CALENDAR TIJDENS ART WEEK IN MEXICO-STAD BIJ SOL A SOL

Sinter Plant Market to Grow by USD 1.3 Billion (2024-2028), Boosted by Advances in Sinter Technology, Report with the AI Impact on Market Trends - Technavio

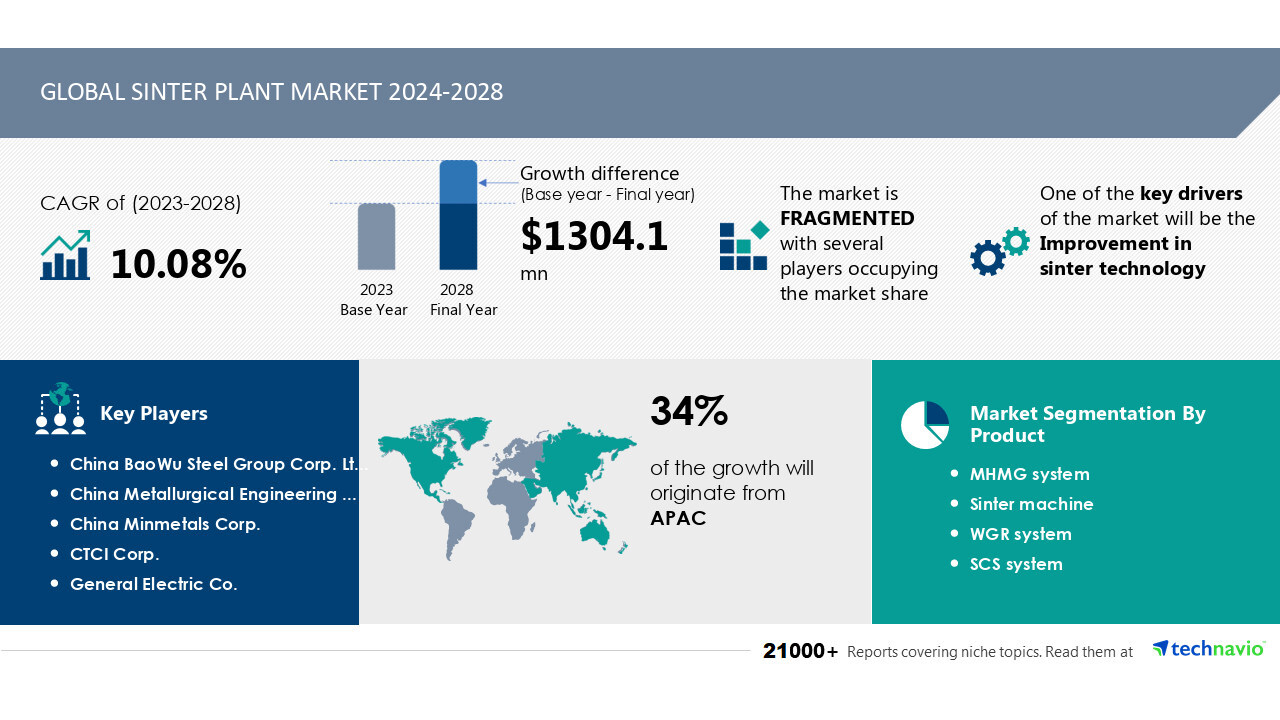

NEW YORK, Feb. 4, 2025 /PRNewswire/ -- Report on how AI is redefining market landscape - The global sinter plant marketsize is estimated to grow by USD 1.3 billion from 2024-2028, according to Technavio. The market is estimated to grow at a CAGR of over10.08% during the forecast period. Improvement in sinter technologyis driving market growth,with a trend towardsimproving power supply infrastructure. However,growing popularity of eaf route poses a challenge. Key market players include China BaoWu Steel Group Corp. Ltd., China Metallurgical Engineering and Project Corp., China Minmetals Corp., CTCI Corp., General Electric Co., Gillanders Arbuthnot and Co. Ltd., Hitachi Ltd., IMASA INGENIERIA Y PROYECTOS SA, Kanikavan Shargh Engineering Co., Larsen and Toubro Ltd., McNally Bharat Engineering Co. Ltd., MECON Ltd., Metso Outotec Corp., Nippon Steel Corp., Perantech GmbH, Primetals Technologies Ltd., Shandong Province Metallurgical Engineering Co. Ltd., Shandong Qingneng Power Co. Ltd., Siemens AG, and Simplex Engineering and Foundry Works Pvt. Ltd..

Key insights into market evolution with AI-powered analysis. Explore trends, segmentation, and growth drivers- View Free Sample PDF

Sinter Plant Market Scope | |

Report Coverage | Details |

Base year | 2023 |

Historic period | 2018 - 2022 |

Forecast period | 2024-2028 |

Growth momentum & CAGR | Accelerate at a CAGR of 10.08% |

Market growth 2024-2028 | USD 1304.1 million |

Market structure | Fragmented |

YoY growth 2022-2023 (%) | 8.91 |

Regional analysis | APAC, North America, Europe, Middle East and Africa, and South America |

Performing market contribution | APAC at 34% |

Key countries | US, India, China, Russia, and Germany |

Key companies profiled | China BaoWu Steel Group Corp. Ltd., China Metallurgical Engineering and Project Corp., China Minmetals Corp., CTCI Corp., General Electric Co., Gillanders Arbuthnot and Co. Ltd., Hitachi Ltd., IMASA INGENIERIA Y PROYECTOS SA, Kanikavan Shargh Engineering Co., Larsen and Toubro Ltd., McNally Bharat Engineering Co. Ltd., MECON Ltd., Metso Outotec Corp., Nippon Steel Corp., Perantech GmbH, Primetals Technologies Ltd., Shandong Province Metallurgical Engineering Co. Ltd., Shandong Qingneng Power Co. Ltd., Siemens AG, and Simplex Engineering and Foundry Works Pvt. Ltd. |

Market Driver

The Sinter Plants Market is experiencing significant growth due to the increasing demand for high-performance materials in various industries. The market includes systems like MHMG, SCS, WGR, and SINTER Machines, used for producing nonflux/acid, self-fluxing, and superflux sinters. These sintering techniques are essential in the metallurgical industry for manufacturing steel components with desirable mechanical qualities. Consumer goods, aerospace, and manufacturing sectors are key consumers of sintered steel. The sintering process involves heating metal powders at high temperatures below their melting point, resulting in improved strength, accuracy, and affordability. Sintered steel is used in brake systems, steering components, and lightweighting applications. The market snapshot includes stainless steel, carbon steel, alloy steel, and tool steel. Rising industrialization, primary exploratory research, and secondary desk research in the metallurgical sector drive market growth. The sintering technology is subject to laws and regulations and changing requirements in industries like automotive, transportation, electrical, and construction. Major sintered steel companies focus on raw materials like iron, steel, tin, nickel, copper, molybdenum, and aluminum. Advancements in materials, such as high-conductivity electric motor cores, battery contacts, connectors, and power electronics, are essential for electric vehicles and their specialized components. Sintering technology offers design freedom, customized parts, and manufacturing efficiency, making it a crucial aspect of industrial growth.

The BF-BOF method, also known as the basic oxygen process, is the preferred choice for steelmaking over the Electric Arc Furnace (EAF) method due to its lower energy intensity. The EAF method relies heavily on electric energy, making it less cost-effective for price-sensitive countries like China, India, and Russia. These nations prioritize meeting consumer demand with their limited power generation capacity. However, recent advancements in power generation technologies have significantly improved electricity conversion factors. Additionally, the enhanced efficiency of consumer devices and the substantial increase in power generation capacity have resulted in a surplus of electricity in many steel-producing nations. Consequently, China, India, and Russia now have sufficient electricity to cater to the needs of an EAF steelmaking process.

Request Sampleof our comprehensive report now to stay ahead in the AI-driven market evolution!

MarketChallenges

- The Sinter Plants Market is a significant segment in the Metallurgical industry, focusing on the production of sintered steel components. The market comprises various systems like MHMG, SCS, WGR, and SINTER Machines, which facilitate the sintering process of Nonflux/Acid, Self-fluxing, and Superflux Sinters. The Sintering process involves melting raw materials, primarily iron, steel, tin, nickel, copper, molybdenum, and aluminum, at high temperatures to produce steel components with desirable mechanical qualities. The challenge lies in ensuring accuracy, affordability, and durability while meeting changing requirements of consumer goods, aerospace, and manufacturing industries. Key challenges include adhering to laws and regulations, addressing environmental concerns, and keeping up with advancements in materials like high-performance and lightweight materials. The market snapshot includes sectors like Stainless Steel, Carbon Steel, Alloy Steel, and Tool Steel, with rising industrialization, urbanization, and industrial growth driving demand. Major players in the market include sintered steel companies, focusing on raw materials, powder composition, sintering conditions, and forged steel alloys to meet the needs of various industries. The market is diverse, catering to sectors like automotive, transportation, electrical, and construction, with applications ranging from brake systems and steering components to engines, transmissions, and electrical appliances. Advancements in manufacturing techniques, such as Powder Metallurgy, Additive Manufacturing (AM), and Conventional Manufacturing, are shaping the market landscape. The future of the Sinter Plants Market lies in addressing material limitations, improving mechanical properties, and enhancing design freedom for customized parts, prototyping, and time-to-market.

- The global steel industry relies heavily on pig iron as a primary raw material, which is produced in blast furnaces. Integrated steel plants use pig iron in Basic Oxygen Furnaces (BOF) to reduce carbon content. However, the production of pig iron in blast furnaces requires substantial capital investment due to the necessity of large-scale production for cost-effective steel manufacturing. Blast furnaces need frequent shutdowns for refractory brick relining, leading to increased operational costs. Additionally, starting up a blast furnace is a time-consuming process, resulting in significant production losses and expenses.

Discover how AI is revolutionizing market trends-Get your access now!

Segment Overview

This sinter plant market report extensively covers market segmentation by

- Product

- MHMG System

- Sinter Machine

- WGR System

- SCS System

- Type

- Small Scale Sinter Plant

- Large Scale Sinter Plant

- Geography

- APAC

- North America

- Europe

- Middle East And Africa

- South America

1.1MHMG system- The Material Handling, Mixing, and Granulation (MHMG) segment is experiencing significant growth in the global sinter plant market. This trend is driven by the declining availability of high-grade iron ore and the increasing focus on energy efficiency in blast furnaces. Advanced sinter plants that can effectively process low-grade iron ore fines are in high demand. To meet this need, vendors in the market offer solutions that include proportioning bins, eliminating the need for raw material mixing at the stockyard. India, China, and African countries are investing in new sinter plants or upgrading existing ones to expand capacity and comply with environmental regulations. In India, the expansion is to support infrastructure projects and meet rising steel demand. In China, modernization is necessary due to stringent environmental regulations. These factors are expected to boost the growth of the MHMG segment in the global sinter plant market during the forecast period.

Download a Sampleof our comprehensive report today to discover how AI-driven innovations are reshaping competitive dynamics

Research Analysis

The Sinter Plant Market encompasses various sintering systems and technologies used to produce steel components with enhanced mechanical qualities for diverse industries. These include MHMG System, SCS System, SINTER Machine, WGR System, and more. The sintering process transforms metal powder into near-net shape parts, suitable for consumer goods, aerospace, automotive, and other sectors. Nonflux/acid sinters, self-fluxing sinters, and superflux sinters are different types of sintering processes, each offering unique advantages. The melting point, accuracy, strength, and affordability of the resulting components vary depending on the specific process and raw materials used, such as stainless steel, carbon steel, alloy steel, tool steel, and powder metallurgy. Advancements in sintering technology, material science, and additive manufacturing (AM) are driving innovation in the market. Applications include brake systems, lightweighting, and electric vehicles, making the sinter plant market a significant contributor to various industries' growth.

Market Research Overview

The Sinter Plants Market encompasses various sintering systems, including MHMG, SCS, WGR, and those used for producing Nonflux/Acid, Self-fluxing, Superflux Sinters. These systems play a crucial role in the Metallurgical industry by transforming steel components from powders into dense, cohesive forms. The sintering process involves heating metal powders to high temperatures below their melting point, resulting in improved mechanical qualities and dimensional correctness. The Sinter Plants Market caters to diverse industries such as Consumer goods, Aerospace, and Manufacturing. The demand for lightweighting, high-performance materials, and advanced manufacturing techniques has fueled the market's growth. Material science and sintering technology have been at the forefront of innovation, leading to the development of Sintered Stainless Steel, Carbon steel, Alloy steel, and Tool steel. Rising industrialization, primary exploratory research, and secondary desk research have contributed to the expansion of the Metallurgical sector. The market snapshot includes applications in various industries like Automotive, Electrical Appliances, Transportation, and Construction. Stainless Steel, Sintered Carbon Steel, and Alloy Steel are popular choices due to their durability, strength, and accuracy. The market is influenced by laws and regulations, changing requirements, and technological advancements. Powder Metallurgy, Additive Manufacturing, and Conventional Manufacturing are some of the manufacturing techniques used in the industry. The demand for lightweight materials, high conductivity, and dimensional accuracy is driving innovation in the market. Sintered steel companies rely on raw materials such as Iron, Steel, Tin, Nickel, Copper, Molybdenum, and Aluminum. The market is witnessing significant growth in the production of specialized components for Electric vehicles, Electrical motor cores, Battery contacts, Connectors, and Power electronics. The market's future looks promising with advancements in materials, manufacturing techniques, and design freedom.

Table of Contents:

1 Executive Summary

2 Market Landscape

3 Market Sizing

4 Historic Market Size

5 Five Forces Analysis

6 Market Segmentation

- Product

- MHMG System

- Sinter Machine

- WGR System

- SCS System

- Type

- Small Scale Sinter Plant

- Large Scale Sinter Plant

- Geography

- APAC

- North America

- Europe

- Middle East And Africa

- South America

7Customer Landscape

8 Geographic Landscape

9 Drivers, Challenges, and Trends

10 Company Landscape

11 Company Analysis

12 Appendix

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio's report library consists of more than 17,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio's comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

Contacts

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email:[emailprotected]

Website:www.technavio.com/

SOURCE Technavio

More Post from the Author

- Redwood Software redfinit l'observabilit de l'automatisation avec Redwood Insights Premium

- Liftoff Announces Confidential Submission of Draft Registration Statement for Proposed Initial Public Offering

- /C O R R E C T I O N -- Educate 360/

- Dan Williams Promoted to Century Fasteners Corp. - General Manager, Operations

- DORSIA DEBUTEERT DE CULTURE CALENDAR TIJDENS ART WEEK IN MEXICO-STAD BIJ SOL A SOL